The year 2020 presents great challenges for all of us, both privately and professionally – to make good use of these special times, I have invested in hardware and software. Prototyping is becoming more and more important as an integral part of the design process, so I have expanded my capabilities here.

With Fusion 360, I have a new CAD tool at hand that leaves virtually nothing to be desired and provides the perfect interfaces for prototype construction. With the integrated sheet metal module, complex sheet metal parts can be designed that can also be produced in small batches at short notice. I can select the best suppliers from my network for the different materials and requirements.

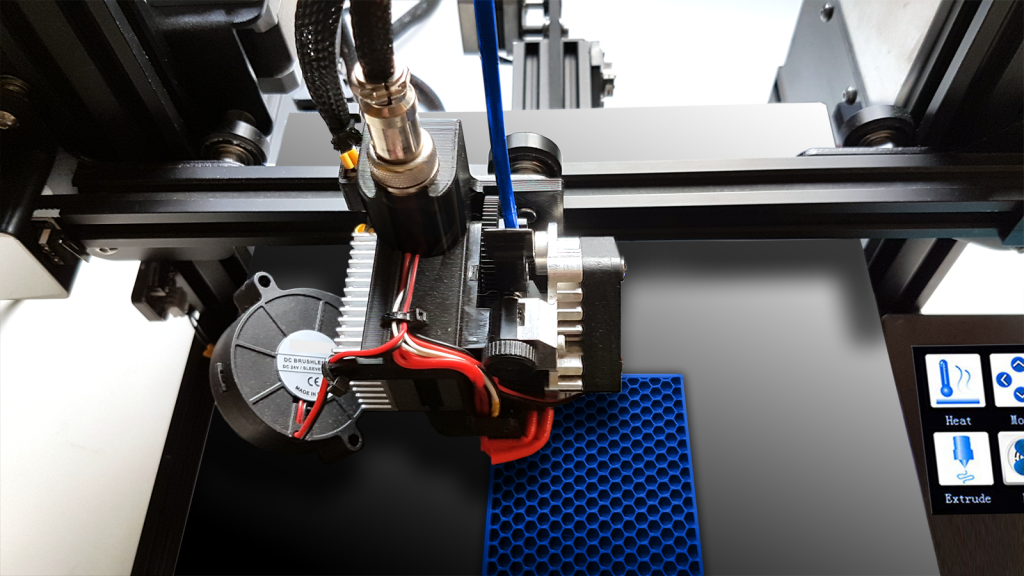

A new interface integrated into Fusion 360 also makes it possible to control the 3D printer almost directly from the programme. Up to now, I have created smaller components in my own workshop using the FDM process without any problems. However, I often came up against limits not only with the dimensions of the components, but also with the materials. That’s why I have now decided to buy an FDM printer with a large build space and an exchangeable, modular print head system. Depending on the required material or resolution, I can choose between different print heads. The range of printable materials extends from soft rubber to very hard-wearing technical plastics. In this way, near-series product characteristics can be guaranteed at a very early stage. Prototypes or design models can be used to identify problems as well as product qualities at an early stage. There are certainly limits to this method, but it is relatively inexpensive, depending on the material.

A new interface integrated into Fusion 360 also makes it possible to control the 3D printer almost directly from the programme. Up to now, I have created smaller components in my own workshop using the FDM process without any problems. However, I often came up against limits not only with the dimensions of the components, but also with the materials. That’s why I have now decided to buy an FDM printer with a large build space and an exchangeable, modular print head system. Depending on the required material or resolution, I can choose between different print heads. The range of printable materials extends from soft rubber to very hard-wearing technical plastics. In this way, near-series product characteristics can be guaranteed at a very early stage. Prototypes or design models can be used to identify problems as well as product qualities at an early stage. There are certainly limits to this method, but it is relatively inexpensive, depending on the material.